Process Control & High Force:

- Matches the complete range of weld cylinder force requirements (over 4,000 lbf).

- Eliminates any requirement to increase gun size in order to gain mechanical advantage for the actuator.

- Typical actuator speed of 250 mm/second (9.8 in/second).

Adaptability:

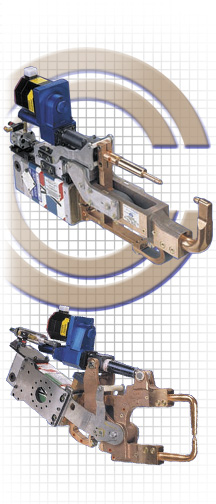

- Same primary components used for "C" style and pinch style gun actuator.

- Can be configured for various motor locations to support a variety of weld gun access requirements.

- With minor changes, it will provide long actuator strokes.

- Can accommodate a range of standard motors.

When used with the Allen Bradley MP Series motor and control solution:

- Tuning and configuration can be accomplished with minimal effort.

- Motor can be changed without additional calibration or tuning.

- Gives full control over actuator force throughout the entire stroke.

- Extended product life.

Has a practical design:

- Belt drive and planetary roller screw design for quiet and trouble-free operation.

- The planetary roller screw does not use ball bearings; the drive nut can be disassembled from the screw and reinstalled without any tools.

- Integral positive stop for establishing a gun open position